Ukwenza ingxaki kunye nokulungiswa kwiI-PCBSUngandindisa ixesha lobomi besekethe. Ukuba i-PCB engalunganga idibene ngexeshaINdibano yePCBInkqubo, ibhodi ye-PCB inokulungiswa ngokusekwe kubume bokungasebenzi kakuhle. Apha ngezantsi kukho iindlela zokulungisa ingxaki kunye nokulungisa i-PCBS.

1. Wenza njani ukulawulwa komgangatho kwi-PCB ngexesha leInkqubo yokwenziwa kwemveliso?

Ngokwesiqhelo, iifektri ze-PCB zinezixhobo ezikhethekileyo kunye neenkqubo eziyimfuneko ezenza ulawulo lomgangatho lwee-PCBs kuyo yonke inkqubo yokuphuhlisa.

1.1.I-AOI ihlola

Uvavanyo lwe-AOI luphawu lokuchitha izinto ezilahlekileyo, icandelo elisebenzayo, kunye nezinye iziphene kwi-PCB. Izixhobo ze-AOI zisebenzisa iikhamera zokufaka imifanekiso emininzi ye-PCB kwaye zithelekise iibhodi zesalathiso. Xa kuchongiwe i-mismatch, inokubonisa iimpazamo ezinokwenzeka.

1.2. Ukuvavanywa kwe-probeng probe

Ukuvavanywa kweprobhodi yokubhabha kusetyenziselwa ukuhambisa isekekethe elifutshane nelivulekileyo, amacandelo angachanekanga (ii-Deds kunye noTraisayo), kunye neziphene kwi-Diode yokhuseleko. Iindlela ezahlukeneyo zePCB zinokusetyenziselwa ukulungisa iimpazamo ze-furm kunye nezahlulo.

1.3.Uvavanyo lwe-FCT

I-FCT (uvavanyo olusebenzayo) ngokuyintloko lujolise ekuvavanyweni kwee-PCB. Iiparamitha zovavanyo zinikezelwa ziinjineli kwaye zinokubandakanya uvavanyo lokutshintsha olulula. Ngamanye amaxesha, iinkqubo ezizodwa zesoftware kunye neefomathi ezichanekileyo zinokufuneka. Uvavanyo olusebenzayo ngokuthe ngqo ukusebenza kwe-PCB phantsi kweemeko zendalo zehlabathi.

I-2. Izizathu eziqhelekileyo zomonakalo we-PCB

Ukuqonda unobangela we-PCB Ukusilela kunokukunceda ukuba uchonge ngokukhawuleza iziphoso zePCB. Nazi ezinye iimpazamo ezixhaphakileyo:

Ukusilela kwecandeloUkutshintsha izinto ezinesiphene kunokuvumela isekethe ukuba isebenze ngokufanelekileyo.

Ukugcwala: Ngaphandle kolawulo olufanelekileyo lobushushu, ezinye izinto zinokutsha.

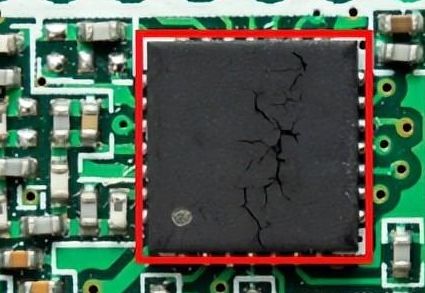

Umonakalo womzimba: Oku kubangelwa kukuphatha kakubi,

Ekhokelela kwi-rocks kumacandelo, amalungu othengi, amagosa omthengisi weMask, umkhondo, kunye neepads.

Ungcoliseko: Ukuba i-PCB iveze kwiimeko ezinzima, umkhondo kunye nezinye izinto zobhedu zinokuchithwa.

3. Ungayifumana njani iingxaki zePCB zePCB?

Ukulandela uluhlu ziindlela ezisi-8:

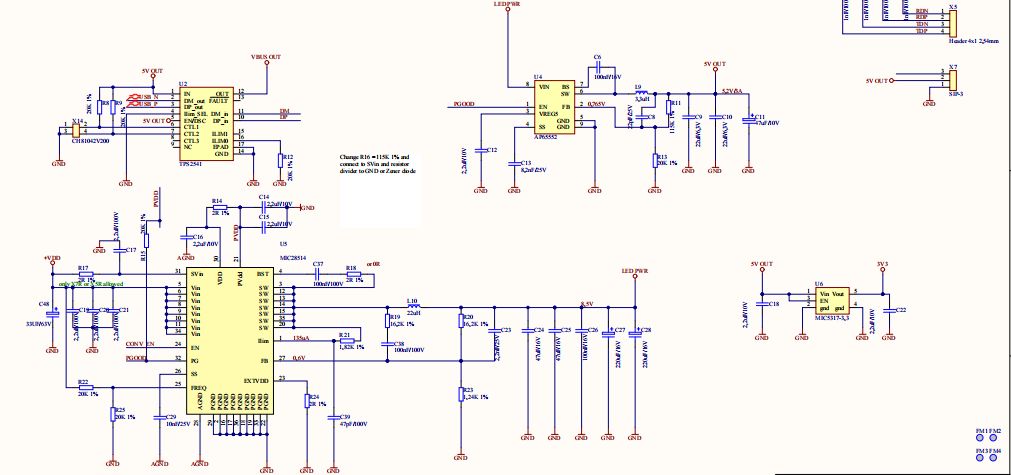

I-3-1. Qonda isikimo sesekethe

Zininzi izinto kwi-PCB, idityaniswe ngokusebenzisa umkhondo wobhedu. Ibandakanya ukuhanjiswa kwamandla, umhlaba kunye neempawu ezahlukeneyo. Ukongeza, zininzi iziphaluka, ezinjengeefilitha, ziphonononge amandla, kunye nezixhobo. Ukuqonda ezi zinto kubalulekile kulungiso lwe-PCB.

Ukwazi indlela yokulandela indlela yangoku kwaye ukwahlukanisa amacandelo anempazamo kuxhomekeke ekuqondeni iisikimo sesekethe. Ukuba isikimo asifumaneki, kunokuba yimfuneko kwi-injini ye-injini yesikimo esekwe kwisimo sePCB.

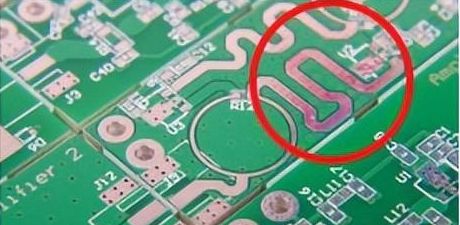

3-2. Uvavanyo olubonakalayo

Njengoko bekutshiwo ngaphambili, ukugqithisa kwesona sizathu siphambili seempazamo zePCB. Naziphi na izinto ezitshisiweyo, umkhondo, okanye udibano lomthengisi unokuchongwa ngokulula xa kungekho galelo laMandla. Eminye imizekelo yeziphene ibandakanya:

-Ukuxhuzula / ukuqhula / izinto ezilahlekileyo

-Umkhondo ohlaziyiweyo

-Udibaniselwano lomthengisi obandayo

-Umthengisi ogqithisileyo

-Izinto ezinamatye

-Iipads / ezilahlekileyo

-Izotha kwi-PCB

Zonke ezi zinokujongwa ngovavanyo olubonakalayo.

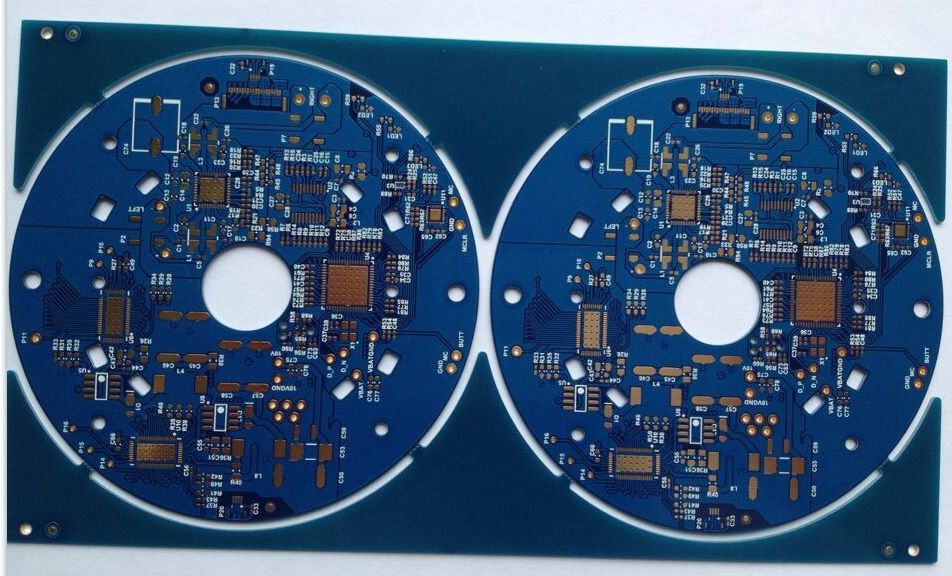

3-3. Thelekisa ne-pcb efanayo

Ukuba unayo enye i-PCB efanayo kunye nokusebenza kakuhle kunye nenye isiphoso, kuya kuba lula kakhulu. Ungalithelekisa ngokwamacandelo, izinto ezisetyenziswayo, kunye neziphene kwimikhondo okanye i-vias. Ukongeza, unokusebenzisa i-Multeter ukujonga ukwenziwa kwegalelo kunye nokufumana iziphumo zomibini iibhodi. Iinqobo ezifanayo kufuneka zifunyanwe kuba ii-PCB ezimbini ziyafana.

3-4. Ukwahlula izinto ezingalunganga

Xa uhlolo olubonakalayo alwanelanga, ungaxhomekeka kwizixhobo ezinje nge-Multer okanyeI-LCR Meyitha. Vavanya icandelo ngalinye ngokusekwe kwiDathasheet kunye neemfuno zoyilo. Imizekelo ibandakanya iziqendu, amachaphaza, amachaphaza, amachaphaza, ii-Dedos, oSetyenzisiweyo, kunye nee-LED.

Umzekelo, ungasebenzisa iseti yediode kwi-Multeter ukujonga ii-Deods kunye nokuHamba. Umqokeleli weququzeleli kunye ne-Emitter ye-Emitter Acts Act njenge-Deds. Ukuze ufumane uyilo lweBhodi yeBhola leSiphaluka, ungajonga imijikelezo evulekileyo nefutshane kuyo yonke uqhagamshelo. Misela nje imitha ukuze uxhathise okanye ukuqhubeka nemowudi kwaye uqhubeke uvavanye unxibelelwano ngalunye.

Xa ufunda iitsheki, ukuba ufunda lungaphezulu kwenkcazo, icandelo lithathwa njengesebenza kakuhle. Ukuba ukufundwayo kukungaqhelekanga okanye ngaphezulu kunokuba bekulindelwe, kunokubakho imiba enamalungu okanye amalungu othengi. Ukuqonda i-voltage elindelekileyo kwiindawo zovavanyo kunokunceda uhlalutyo lwesekethe.

Enye indlela yokuvavanya izinto kukuhlalutywa kwe-nodal. Le ndlela ibandakanya ukusebenzisa i-voltage kwizinto ezikhethiweyo ngelixa ingankcenkceshela yonke isekethe kwaye ilingane iimpendulo ze-Voltage (impendulo ye-V-Rekso). Chonga zonke iindawo kwaye ukhethe ireferensi exhunyiwe kwizinto ezibalulekileyo okanye imithombo yamandla. Sebenzisa umthetho wangoku we-Kirchhoff (KCL) ukubala i-node engaziwayo Ukuba kukho imiba ebonisiweyo kwindawo ethile, ibonisa impazamo kuloo ndawo.

Iisekethe ezihlanganisiweyo zinokuba ngumsebenzi omkhulu ngenxa yobunzima babo. Nazi ezinye iimvavanyo ezinokwenziwa:

-Chonga onke amanqaku kunye novavanyo i-IC usebenzisa uhlalutyo lwe-Logic okanye iI-Oscilloscope.

Jonga ukuba i-IC ijolise ngokuchanekileyo.

- Qinisekisa ukuba onke amalungu orhwebo aqhagamshelwe kwi-Ic zikwimeko elungileyo yokusebenza.

- Vavanya imeko yalo naluphi na u-swinks oshushu okanye iipads ze-thermal ezinxulumene ne-IC yokuqinisekisa ukwahlula-shintsha ngamandla.

3-6. Ukuvavanywa kwamandla amandla

Ukufikelela kwimicimbi yokuhambisa amandla, kuyimfuneko ukulinganisa i-voltages yololiwe. Ukufundwa kwi-Voltmeter kunokubonakalisa igalelo kunye nexabiso lokuphuma kwamacandelo. Utshintsho kwi-voltage inokubonisa iingxaki ezinokubakho. Umzekelo, ukufundwa kwe-0V kuloliwe kunokubonisa isekethe emfutshane kwicandelo lokuhambisa amandla, kukhokelela kwicandelo lokuthatha inxaxheba. Ngokwenza uvavanyo lokugcina amandla kwaye uthelekise amaxabiso alindelekileyo kwimilinganiselo yamandla, ukubonelelwa ngamandla okuba nzima kunokuba bodwa.

3-7. Ukuchonga ii-hotspots zesekethe

Xa iziphene ezibonakalayo azinakufunyanwa, ukuhlolwa komzimba ngenaliti yamandla kunokusetyenziselwa ukuvavanya isekethe. Unxibelelwano olungalunganga lunokuvelisa ubushushu, olunokuziva lubeka isandla kwiBhodi yeSiphaluka. Olunye ukhetho kukusebenzisa ikhamera yokucinga ye-thermal, edla ngokukhethwa kwisekethe ephantsi kwe-voltage. Izilumkiso zokhuseleko eziyimfuneko kufuneka zithathwe ukuphepha iingozi zombane.

Enye indlela kukuqinisekisa ukuba usebenzisa isandla esinye sovavanyo. Ukuba indawo eshushu ifunyenwe, kufuneka ipholelwe phantsi, kwaye zonke iindawo zonxibelelwano kufuneka zitshekishwe ukujonga apho umba uxoka.

I-3-8. Ukucocwa kweendlela zokwenza umqondiso

Ukusebenzisa obu buchule, kubalulekile ukuba siqonde amaxabiso alindelekileyo kunye namagqabi kwiindawo zovavanyo. Uvavanyo lwe-Voltage lunokwenziwa kumanqaku ahlukeneyo usebenzisa i-Multeter, Oscillocope, okanye nasiphi na isixhobo sokufaka idatha. Ukuhlalutya iziphumo zinokunceda ekwenzeni iimpazamo.

4. Izixhobo ezifunekayoUkulungiswa kwe-PCB

Ngaphambi kokuqhuba nakuphi na ukulungiswa, kubalulekile ukuqokelela izixhobo ezifanelekileyo zomsebenzi, njengoko intetho ihamba, 'isitshixo sokuqaqanjelwa singayiceki iinkuni.'

● Ukuxhotyiswa okusebenzayo ngokuxhonywa komhlaba, iziseko zamandla, kunye nokukhanya kubalulekile.

.

● Inkqubo yokuntywila ngokuchanekileyo iyafuneka ukuze ivulwe kwaye ivulwe nge-hole ngexesha lenkqubo yokulungisa. Le nkqubo ivumela ulawulo ngaphezulu kobubanzi kunye nobunzulu beentyatyambo.

● Intsimbi elungileyo yomthengisi iyimfuneko kumashishini athengiswayo ukuze aqiniseke ukubaluleka kwetyala elifanelekileyo.

● Ukongeza, i-elektroplating inokufuneka nayo.

● Ukuba i-Mask Mask Mateer yonakalisiwe, kuya kufuneka ilungiswe. Kwiimeko ezinjalo, umaleko we-epoxy ream ukhetha.

I-5. Ukuthatha amanyathelo okhuseleko ngexesha lokulungiswa kwe-PCB

Kubalulekile ukuthatha amanyathelo okhuseleko ukunqanda iingozi zokhuseleko ngexesha lenkqubo yokulungisa.

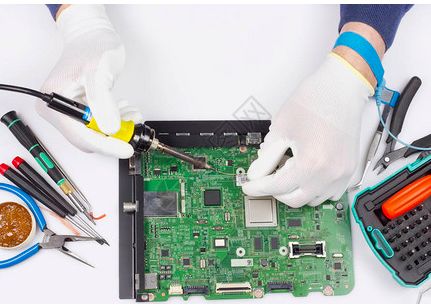

● Izixhobo zokhuselo: Xa ujongene namaqondo obushushu aphezulu okanye amandla aphezulu, ukunxiba izixhobo zokukhusela yiyo. Iiglasi zokhuseleko kunye neegloves kufuneka zinxitywe ngexesha lokurhweba nokuqhuba, ukukhusela kwiingozi zemichiza ezinokubakho.

Ndinxibe iigloves ngelixa ilungisa i-PCBS.

● Ukukhutshwa kwe-electrostatic (e-ESD): ukuthintela ukonakala kombane okubangelwa yi-ESD, qiniseka ukuba ukhuphe umthombo wamandla kwaye ukhuphe naluphi na umbane oshiyekileyo. Unganxiba kwakhona ii-wristbands ze-wristband okanye usebenzise i-anti-static mats ukuya kuthoba umngcipheko we-ESD.

6. Ungayilungisa njani i-PCB?

Iimpazamo eziqhelekileyo kwi-PCB zihlala zibandakanya iziphene kwimikhondo, izinto kunye neepads zomthengi.

I-6-1. Ukulungisa umkhondo owonakeleyo

Ukulungisa umkhondo owonakalisiweyo okanye owonakeleyo kwi-PCB, sebenzisa into ebukhali ukuze ibhenca indawo yomphezulu womkhondo wokuqala kwaye isuse imaski yeThutho. Coca indawo yobhedu nge-solvent yokususa nayiphi na inkunkuma, inceda ekufezekiseni ukuqhubeka kombane okungcono.

Ngenye indlela, ungakwazi ukuthengisa i-jumper wine ukulungisa umkhondo. Qinisekisa ukuba ubutshintsho be-wire dibanisa ububanzi bendlela yokuhamba ngomkhondo.

6-2.Ukutshintsha izinto ezingalunganga

Ukutshintsha izinto ezonakeleyo

Ukususa izinto ezingalunganga okanye igosa eligqithileyo elivela kumalungu eThuthi, kuyafuneka ukunyibilikisa umrhwebi, kodwa kufuneka kuthathwe isilumkiso ukunqanda ukuvelisa uxinzelelo lomhlaba kwindawo ejikelezileyo. Ukulandela la manyathelo angezantsi ukuze athathe indawo yezinto ezisekhompyutha:

● Ukufudumeza umanyano lwabathengi ngokukhawuleza kusetyenziswa isinyithi okanye isixhobo sokuphazamiseka.

● Nje ukuba umrhwebi anyibilikisiwe, sebenzisa impompo yokutya ukuze ususe ulwelo.

● Emva kokususa lonke uqhagamshelo, icandelo liya kutsalwa.

● Emva koko, dibanisa icandelo elitsha kunye nomthengisi endaweni.

● Ukucofa ubude beli candelo kukhokelela kusetyenziswa ii-wires ezisikiweyo.

● Ukuqinisekisa ukuba i-terminals iqhagamshelwe ngokwehombo elifunekayo.

6-3. Ukulungisa iipads zethengi

Ngamaxesha ahamba, iipads zomthengisi kwi-PCB inokuphakamisa, ikhuba, okanye ikhefu. Nazi iindlela zokulungisa iipads zeThuthi

Iipads zeThokhwe: Ukucoca indawo nge-isolvent usebenzisa i-witton swab. Ukubhobhoza i-pad ibuyiselwe endaweni ye-Epoxy ePhezulu kwiThufa kwi-Pormer kwaye ichaphazele, ukuvumela i-Eposn, ivumela i-Epoxy Retin ukuze iqhubeke nenkqubo ethengisayo.

Iipads ezonakalisiweyo okanye ezingcolisekileyo zeThuqu: Susa okanye unqumle i-positi eyonakalisiweyo, eveza umkhondo oxhunyiweyo ngokukrola imaski yomthengi ejikeleze i-pad. Coca indawo ene-isolvent usebenzisa i-swab yekotoni. Kwipali entsha yomthengisi (edityaniswe kumkhondo), sebenzisa ungqimba we-epoxy ye-epoxy kwaye uyikhusele endaweni. Emva koko, yongeza i-epoxy ren phakathi komkhondo kunye ne-jodi pad. Nyanga ngaphambi kokuba uqhubeke nenkqubo ethengisayo.

I-Shenzhen Anke PCB CO., LTD

2023-7-20

IXESHA LOKUQALA: UJUL-21 ukuya kwi-2023