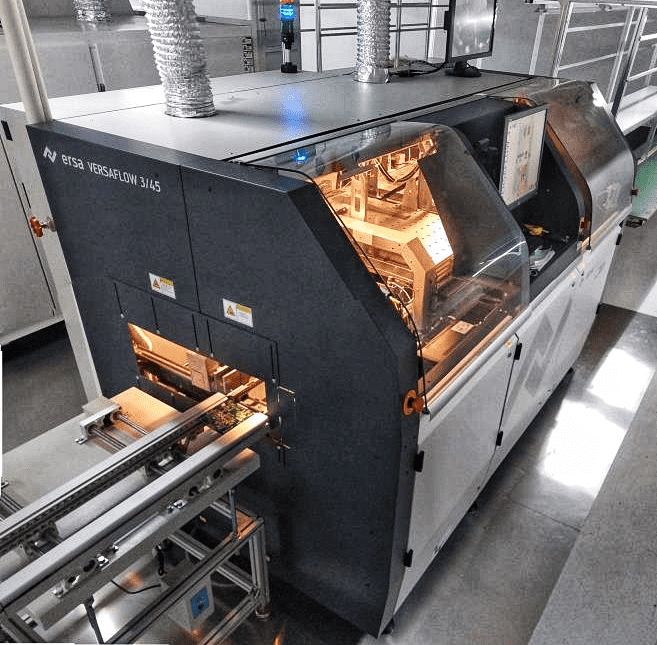

Kwinkqubo yokuthengisa ye-PCBA, ukuthengiswa kwezinto ezifakwe kwiplagi kwi-PCBA kudla ngokubandakanya ukuthengiswa kwamaza okwenziwa ngesandla okanye i-automated wave soldering, ebandakanya ukuphepha imathiriyeli ye-SMT enyuswe phezulu kunye nemingxuma ethile engeyiyo enkonkxiweyo, efuna ukwenziwa ngokwezifiso kwezixhobo zokuthambisa.Oku kubangela iindleko ezongezelelweyo zokulungisa, ukunyuka kokusetyenziswa kwe-solder ngenxa yokwanda kwendawo ye-tin, ukusetyenziswa kwamandla aphezulu, kunye nongcoliseko olubalulekileyo.Ngokukodwa ekujonganeni nemingeni yokuvelisa iibhetshi ezincinci kunye neentlobo ezahlukeneyo zeemveliso, ixesha elifunekayo lokulungiswa kwempahla kunzima ukuhlangabezana nayo.Ukuze ufezekise ngcono izibophelelo ekusebenzeni kakuhle kunye nomgangatho, ngakumbi ekufezekiseni iimfuno ze-welding yeemveliso eziphezulu kumashishini afana neenqwelo-moya, inqwelomoya, i-aerospace, kunye nomkhosi, i-ANKE PCB isandula ukuzisa itekhnoloji yokuthengisa i-wave ephezulu kakhulu kwihlabathi. , Umatshini wokuthengisa owenziwe ngamaza eJamani owenziwe ngu-ERSA VERSAFLOW 3/45.Lo matshini unciphisa ngokucokisekileyo kwaye unciphise imiba ekhankanywe ngasentla, ukuphucula ukusebenza kakuhle, ukuthembeka komgangatho, kunye nokuzinza kweemveliso ezithengiswayo.

Xa kuthelekiswa nokuthengiswa kwamaza emveli, esi sixhobo sinezi mpawu zilandelayo:

● Ukuziqhelanisa ngokuzenzekelayo kwiPCB

Ngaphantsi kokulungelelaniswa kwenkqubo ye-MES, inokubiza ngokuzenzekelayo inkqubo ye-welding ngokusebenzisa ukuqatshelwa kwekhowudi ye-QR kwiibhodi ezahlukeneyo ze-PCB, kwaye ifezekise ukutshintsha ngokukhawuleza kwi-intanethi;

● Umgangatho othembekileyo ngakumbi

I-ERSA ekhethiweyo ye-wave soldering ibonelela ngomgangatho olungileyo we-welding - ukuzinza kwemveliso kunye nesantya sokuthembeka kunokufikelela kwi-99.999%.Ibiza ngokuzenzekelayo inkqubo ye-welding esele isetyenzisiwe ukufezekisa ukulungiswa kwe-intanethi kwexesha le-welding kunye nomthamo we-solder ngokweemfuno ze-welding zamacandelo ahlukeneyo.Oku kuphelisa ukufudumeza okuphezulu kwesixhobo okanye ukufudumeza ngaphantsi kwaye kuqinisekisa ukuba akukho bhulorho ye-solder okanye i-voids, okukhokelela kumalungu athandeka ngobuhle.

● Ukunciphisa ukusetyenziswa kwe-solder

Ukuthengiswa kwamaza okuqhelekileyo kufuna uluhlu lwe-solder olungaphezulu kwe-400KG, kwaye i-solder kufuneka iqhubeke inyibilika kwaye iphazamise, okukhokelela malunga ne-1KG / H yenkunkuma ye-solder.Ngokwahlukileyo koko, i-ERSA ifuna kuphela uluhlu lwe-solder lwe-10KG kwibhafu nganye, ivelisa kuphela malunga ne-2KG yenkunkuma ye-solder ngenyanga.Ngethuba lenkqubo ye-soldering, i-iron soldering ikhuselwe yi-99.999% yegesi ye-nitrogen, iqinisekisa ukuba i-100% ye-solder isetyenziswe kwi-solder joints kunye nokunciphisa ukuveliswa kwe-solder dross.Olu phawu aluqinisekisi kuphela ukucoceka kwendawo yokuthungatha kodwa luphucula kakhulu umgangatho we-solder kwaye kunciphisa kakhulu ukusetyenziswa kwe-solder.

● Ukuwonga umbane ngakumbi kwaye kunobungani nokusingqongileyo

I-ERSA selective wave soldering inamandla ombane - ukusetyenziswa kwamandla yi-12KW kuphela, eyi-1/4 ye-wave soldering eqhelekileyo.I-ERSA yokukhetha i-wave soldering isusa imfuno yokuchitha ixesha kunye neendleko ezikhethekileyo zokulungiswa kwebhetshi yokuvelisa i-wave soldering eqhelekileyo.Ibhafu ye-solder efudumeleyo kunye nokufudumeza kwangaphambili okuzenzekelayo okuzenzekelayo kunciphisa ukusetyenziswa kwamandla malunga ne-25%.Indlela ezenzekelayo yokutshiza inqaku lokudibanisa i-solder inciphisa ngokubonakalayo ukusetyenziswa kwezinto eziguquguqukayo ezingahambelani nokusingqongileyo malunga ne-80% kwaye inciphisa kakhulu ungcoliseko oluvela kwiintsalela zeekhemikhali eziveliswe ngexesha lenkqubo yokucoca i-PCB kamva malunga ne-70%.

Emva kokuqaliswa kunye nokugunyaziswa kwe-German ERSA ekhethiweyo inkqubo yokuthengisa amaza, inqanaba lokuqala lomgangatho odibeneyo we-solder we-ANKE PCB's plug-in components (ezifana nezihlanganisi, iibhloko ze-terminal, njl.) iye yanda ukusuka kwi-91,3% ukuya kwi-99,9%.Oku kuye kwajongana kakhulu nemingcipheko esemgangathweni kunye neengozi ezinokwenzeka kule nkqubo ebalulekileyo, ukubonelela ngesiqinisekiso esiqinileyo nesaneleyo sokuthembeka kwe-soldering kunye nokuzinza kweemveliso eziphezulu zabathengi.Iququzelela inguqu ekhawulezileyo yophando kunye nophuhliso oluphunyeziweyo kwimpahla ethengiswayo kwaye ikwavuma uphuhliso oluzinzileyo lweemveliso.

Shenzhen ANKE PCB Co.,LTD

2023-8-22

Ixesha lokuposa: Aug-23-2023