Iphaneli yePCBimithetho kunye neendlela

1. Ngokweemfuno zenkqubo yeefektri zendibano ezahlukeneyo, ubungakanani obukhulu kunye nobukhulu obuncinci bephaneli kufuneka buqondwe ngokucacileyo.Ngokubanzi, i-PCB encinci kune-80X80mm kufuneka ifakwe kwipaneli, kwaye ubungakanani obukhulu buxhomekeke kumthamo wokusetyenzwa komzi-mveliso.Ngamafutshane, ubungakanani bepcb kufuneka bufezekise imfuno yeIzixhobo ze-SMTizinto ezifakwayo, ezilungele ukusetyenzwa kwepetshi ye-SMT kunye nokunceda ukugqiba ubukhulu bebhodi yePCB.

2. Indibano kunye ne-sub-boarding kufuneka ihlangabezane neemfuno ze-DFM kunye ne-DFA, kwaye kwangaxeshanye kuqinisekiswe ukuba indibano yePCB ilungisiwe kwaye ayikhubazeki lula emva kokubekwa kwi-fixture.I-groove yokwahlula phakathi kweepaneli kufuneka ihlangabezane neemfuno zokunyuka komphezulu ngexeshaPCBAukusetyenzwa kwetshiphu.

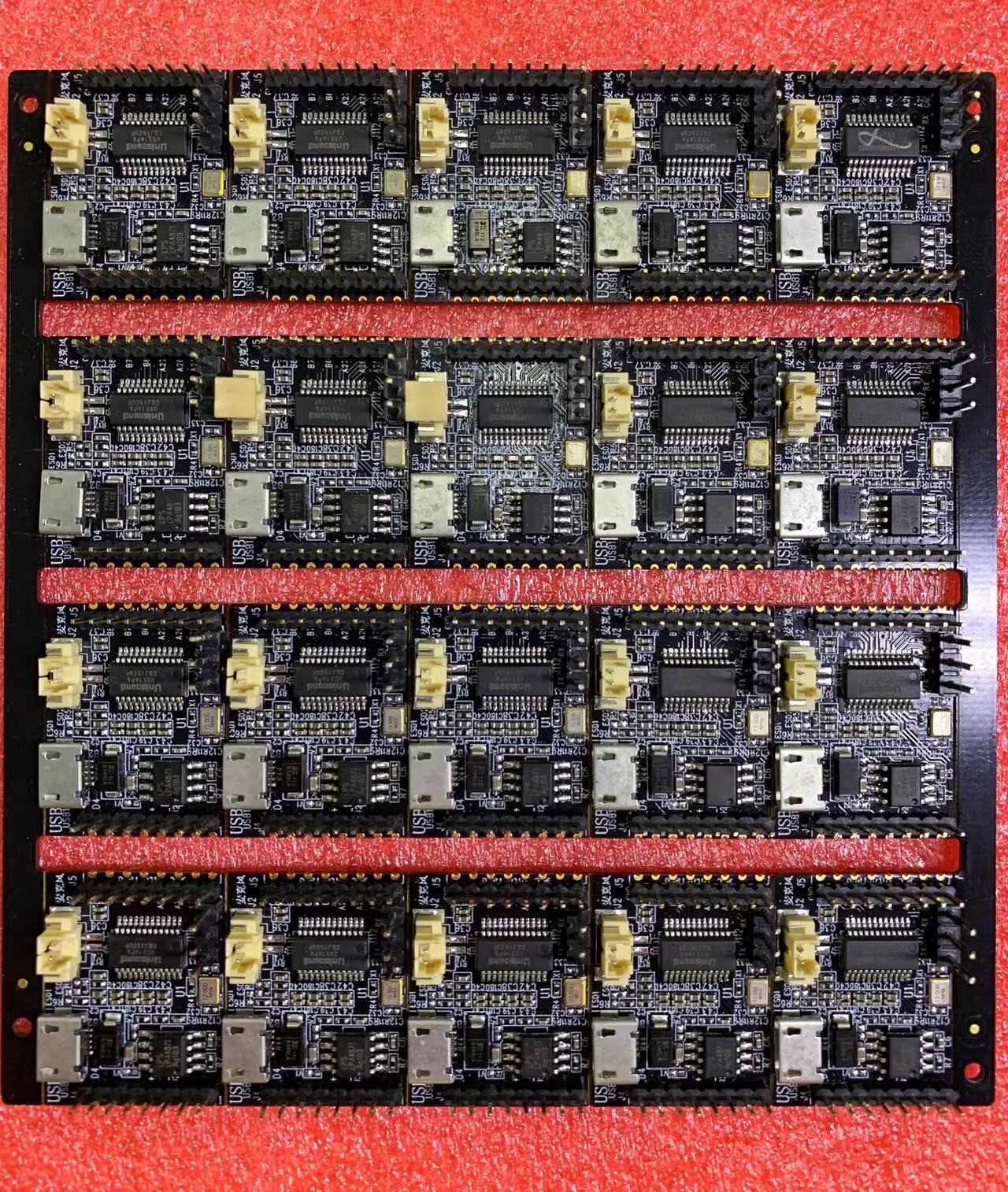

3. Kwiphaneli yePCBuyilo, ukucwangciswa kwamacandelo kufuneka kugweme ukuhlukana koxinzelelo kwaye kubangele ukuqhekeka kwecandelo.Ukusetyenziswa kwesakhiwo sepaneli esifakwe ngaphambili kunokunciphisa i-warpage kunye ne-deformation ngexesha lokuhlukana kwebhodi, kunye nokunciphisa uxinzelelo kumacandelo.Ubuncinci, zama ukungabeki ixabisoamacandeloOkulandelayokwicala lenkqubo.

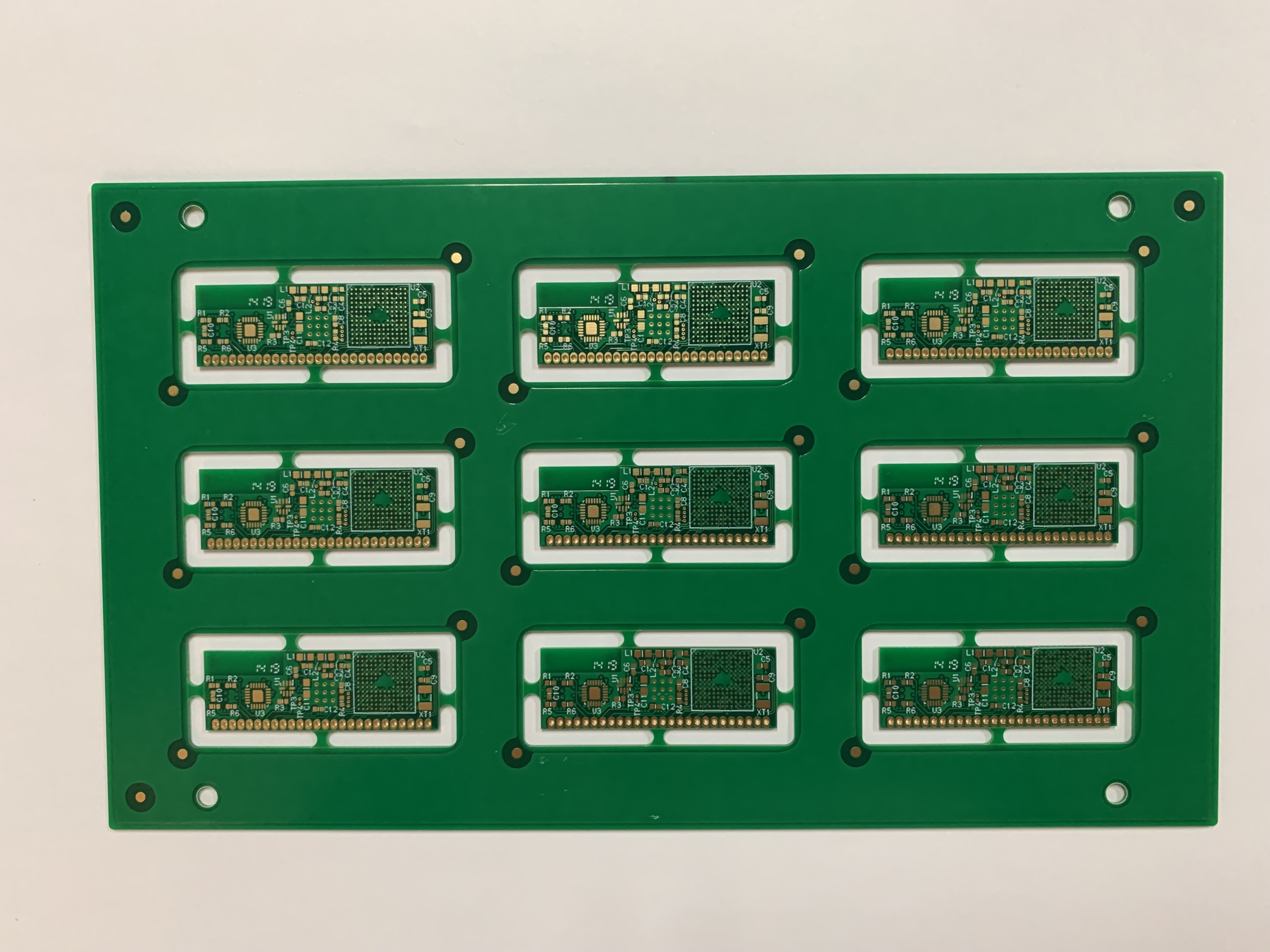

4. Ubungakanani kunye nefom yephaneli iphathwa ngokuhambelana neprojekthi ethile, kwaye imbonakalo yembonakalo isondele kwisikwere ngokusemandleni.Kucetyiswa ngamandla ukusebenzisa indlela yephaneli ye-2 × 2 okanye 3 × 3.Akukhuthazwa ukudibanisa iipaneli ze-yin kunye ne-yang ukuba akukho mfuneko;

5. Xa umzobo webhodi edibeneyo yokudibanisa ibhodi idlula ukuphazamiseka phakathi kweebhodi ezidibeneyo ezininzi, ixazululwa ngokujikeleza i-joint + yenkqubo yecala ukukhusela umgangatho ombi womonakalo wokungqubana ngexesha lokuhanjiswa okanye ukusingatha inkqubo.emva kwe-welding.

6. Emva koyilo lwephaneli, kufuneka kuqinisekiswe ukuba umda wendawo yesalathiso yebhodi enkulu ubuncinane yi-3.5mm kude nomda webhodi (uluhlu oluncinci lomatshini obamba umda we-PCB yi-3.5mm. ), kunye neendawo ezimbini zokubhekisela kwi-diagonal kwibhodi enkulu ayinakubekwa ngokulinganayo.Musa ukubeka amanqaku ereferensi ngokulinganayo, ukuze umva/umva icala lePCB lingangena kumatshini ngomsebenzi wokuchonga wesixhobo ngokwaso.

7. Xa ubukhulu beibhodi PCBingaphantsi kwe-1.0mm, amandla ebhodi yolawulo yonke iya kuncitshiswa kakhulu (ibuthathaka) xa i-splicing joint okanye i-v-cut groove yongezwa, kuba ubunzulu be-V-cut yi-1/3 yobukhulu bebhodi , Umbindi we ibhodi PCB isetyenziselwa amandla, kwaye inxalenye skeleton exhasayo - ilaphu iglasi ifayibha V yaphukile, kubangele ukuthamba okubalulekileyo amandla.Ukuba ayixhaswanga yi-jig, iya kuchaphazela inkqubo engezantsi kwe-PCBA.

8. Xa kukhoiminwe yegolidekwi-PCB, beka ngokubanzi iminwe yegolide ngaphandle kwebhodi kwicala lendawo engaqhawukiyo.Umphetho womnwe wegolide awunakuxutywa okanye uqhutywe.

Shenzhen ANKE PCB Co.,LTD

Ixesha lokuposa: Apr-04-2023