Ngotshintsho olukhawulezileyo kobomi bangoku obudala bufuna iinkqubo ezongeziweyo ezifuna ukwenza intsebenzo yeebhodi zesekethe zakho ngokunxulumene nokusetyenziswa kwabasebenzi kunye nokuphucula ukuSebenza kweZicwangciso-nkqubo zokuSebenzisa i-Tech yeTekhnoloji.

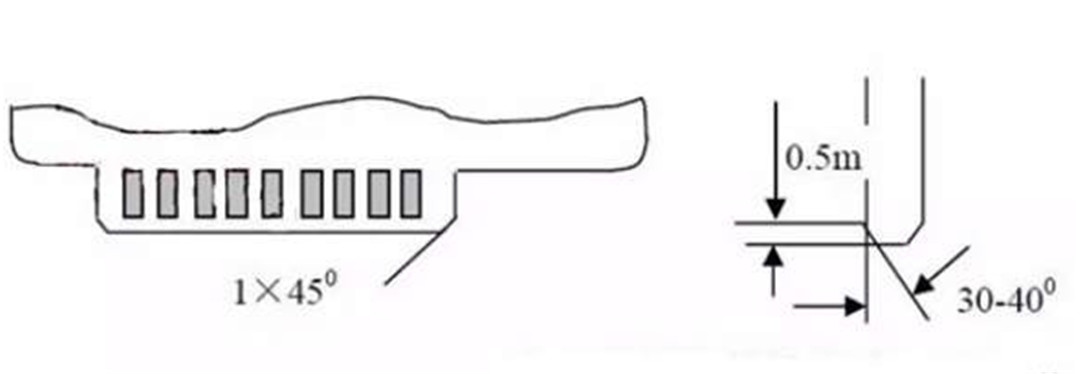

Umnxibelelanisi we-Edding Teve veer wegolide

Umnxibelelanisi we-Edring veeulls uqhubela phambili kwiminwe yegolide yeBhodi yeGeble yeGeble okanye iBhodi ye-Ins, kukusika okanye ukubekwa komqambi we-angle. Nawuphi na umnxibelelanisi wePCI okanye enye into yenza kube lula ukuba iBhodi ingene kwi-nxibelelanisi. Umnxibelelanisi we-Edring Teeccralling yiparameter kwiinkcukacha ze-oda ekufuneka ukhethe kwaye ujonge olu khetho xa kufuneka njalo.

I-Carbon Printa

I-Carbon Printa yenziwa nge-inki yekharbon kwaye inokusetyenziselwa oonxibelelwano lwebhodi yezitshixo, abafowunelwa be-LCD kunye ne-jumpers. Ukuprintwa kwenziwa nge-inki yekhabhoni esebenzayo.

Izinto zekhabhoni kufuneka zixhathise ukuthengisa okanye i-HAL.

Ukufakelwa okanye ububanzi bekharbon akunakunciphisa ngaphantsi kwe-75% yexabiso elichanekileyo.

Ngamanye amaxesha imaski ye-peelable iyimfuneko ukukhusela ngokuchasene ne-fluxes esetyenzisiweyo.

I-Teelament MABHISEKILEK

I-Teelament Fortermask i-Speelable I-Teelable Ukungasebenzi isetyenziselwa ukugubungela iindawo ezingathengi ngexesha lenkqubo yeThufa yeThuthi. Olu nguqili lube butyhilekayo lunokususwa emva koko lususwe ngokulula ukuze lushiye iipads, imingxunya kunye neendawo ezithengiswayo ngemeko efanelekileyo kwiinkqubo zendibano zesikolo kunye necandelo / uqhagamshelo.

I-Vais kwaye iRiayid Vais

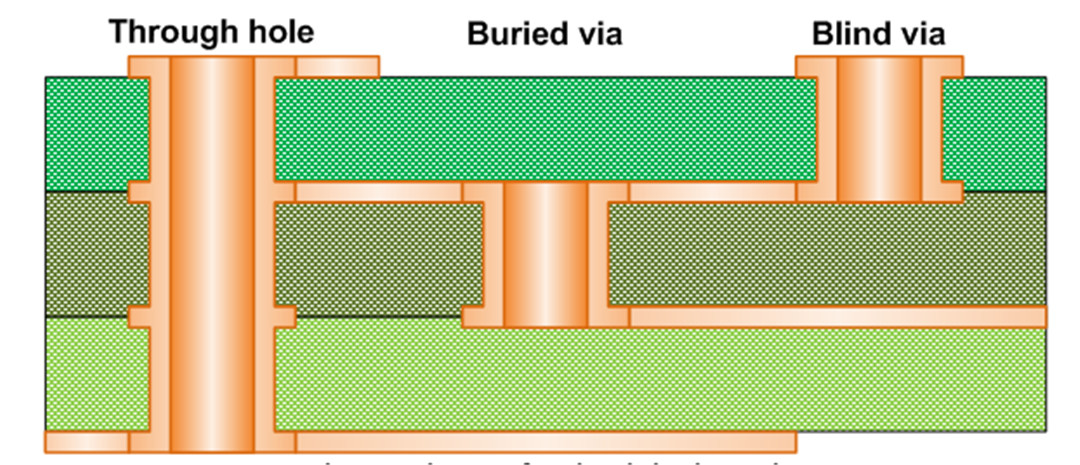

Yintoni eyimfama nge

Kwimfama nge-on, i-hia inxibelelanisa umaleko wangaphandle ukuya kuthi ga kwi-PCB enye okanye engaphezulu ye-PCB kwaye inoxanduva lokuqulunqwa phakathi kwe-subter ephezulu kunye nezimbo zomntu ongaphakathi.

Yintoni ingcwatywayo nge-vale?

Kwi-wid engcwatywe, kuphela ibhodi yangaphakathi yeBhodi iqhagamshelwe nge-hico. "Ingcwatywe" ngaphakathi kwibhodi kwaye ayibonakali ngaphandle.

Imfama kwaye ingcwatywe iluncedo ngakumbi kwiibhodi ze-HDI ngenxa yokuba ziQhetshwa kweBhodi yokungasebenzi

Ungayenza njani imfama

Ngokubanzi asisebenzisi i-laser enobuthathaka ilawule ilawulayo ukuba ibe yimfama kwaye ingcwatywe uVias. Okokuqala sigqobhoza isisu esinye okanye ngaphezulu kunye neplate kwimingxunya. Emva koko siyakha kwaye sicinezele i-stack. Le nkqubo ingaphindwa izihlandlo ezininzi.

Ithetha ukuba:

I-1. I-riso ihlala inqumle inani leendawo zobhedu.

I-2. A hi ayinakuphela kwicala elingaphezulu lesiseko

I-3. A Via ayinakuqala kwicala elingaphantsi le-core

I-4.

Ulawulo lokunyanzela

Ulawulo lokunyanzela lube lelinye lezinto ezixhalabisayo kunye neengxaki ezinzima kwi-PCB ye-PCB ephezulu.

Kwizicelo ezinde eziphakamileyo, ukuqhutywa kwerediyo elawulwayo kusinceda ukuba siqiniseke ukuba imiqondiso ayinantlonelo njengoko benza i-PCB.

Ukuxhathisa nokusabela kwesekethe yombane kunefuthe elibonakalayo ekusebenzeni, njengoko iinkqubo ezithile kufuneka zigqitywe phambi kwabanye ukuqinisekisa ukusebenza ngokufanelekileyo.

Ngokuyintloko, ukuphakanyiswa okulawulwayo kukuthelekisa iipropathi zezinto ezibonakalayo ezinobungakanani beempawu ze-trace kunye neendawo zokuqinisekisa ukuba ukonakalisa umqondiso womkhondo ukwipesenti ethile yexabiso elithile.