ImingxunyaI-PCBIngachazwa ukuba ifakwe kwi-HoEs

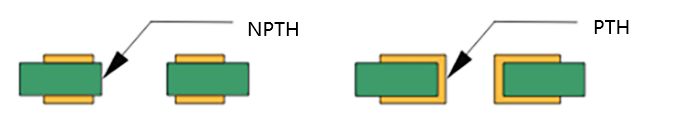

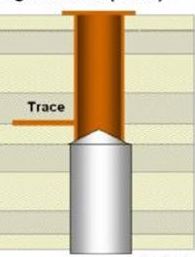

Ipakishwe ngomngxunya (i-PTH) ibhekisa kumngxunya wokudibana kwentsimbi eludongeni lwayo, olunokufumana unxibelelwano lombane phakathi kwepateni engaphakathi, i-PCB engaphandle, okanye zombini i-PCB. Ubungakanani bayo bugqitywe bubukhulu bomngxunya otyhafileyo kunye nobungqingqwa bomaleko obekiweyo.

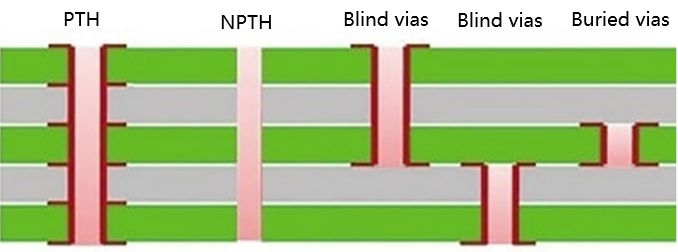

Ukungafakwa kwimingxunya (i-Npth) yimingxunya engathathi nxaxheba kunxibelelwano lombane kwi-PCB, ekwabizwa ngokuba yimingxunya engafakwanga. Ngokutsho koluhlu umngxunya ungene kwi-PCB, imingxunya inokuhlelwa njenge-Hole, ingcwatywe nge / kumngxunya, kwaye ingaboni ngamehlo.

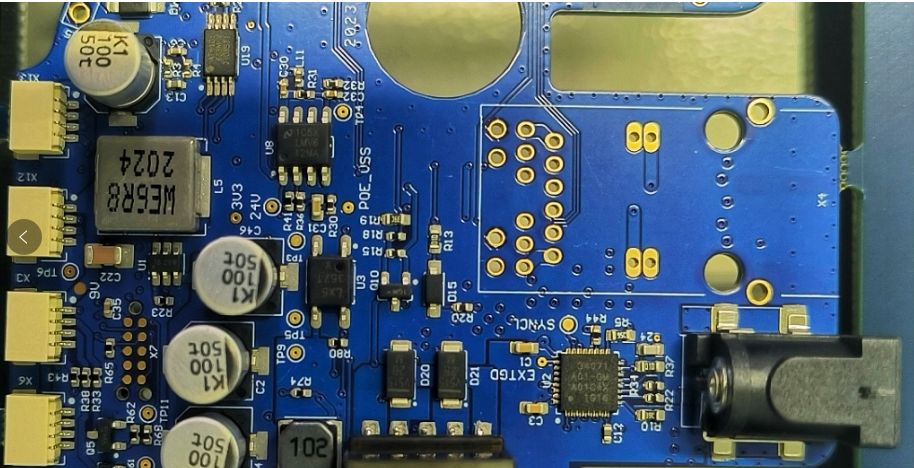

Ngemingxunya ingena kuyo yonke i-PCB kwaye inokusetyenziselwa uqhagamshelo lwangaphakathi kunye / okanye ukuma kunye nokuphakanyiswa kwamacandelo. Phakathi kwazo, imingxunya esetyenziselwa ukulungisa kunye / okanye unxibelelwano lombane nezixhobo zecandelo (kubandakanya izikhonkwane kunye neengcingo) kwi-PCB zibizwa ngokuba yimingxunya yecandelo. Ipeyintiwe kwimingxunya yangaphakathi esetyenziselwa unxibelelwano lwangaphakathi kodwa ngaphandle kwecandelo lokukhwela okanye ezinye izinto zokuqiniswa zibizwa ngokuba yimingxunya. Kukho iinjongo ezimbini zokugrumba ngemingxunya kwi-PCB: Inye yeyokudala ukuvulwa kwiBhodi, ivumela iinkqubo ezilandelayo zokwenza uqhagamshelo lombane phakathi kweBhodi yeBhodi; Enye into kukugcina ingqibelelo kunye nokuchaneka kokubekwa kofakelo lwecandelo kwiBhodi.

I-Vias engaboniyo kunye ne-Vias isetyenziswe ngokubanzi kwi-proccoct exineneyo-teknoloji ye-HDI ye-HDI, ubukhulu becala kwiBhodi yePCB ephezulu. I-Vias ye-Vias iqhele ukudibanisa umaleko wokuqala kungqimba lwesibini. Kwezinye iindlela, i-vis eyimfama ikwanokuqhagamshela umaleko wokuqala kuludwe lwesithathu. Ngokudibanisa ukungaboni kwaye ukungcwaba i-VIAS, unxibelelwano olungaphezulu kunye nokuxinana okuphezulu kweBhodi ePhakamileyo efunekayo kwi-HDI inokufezekiswa. Oku kuvumela ukwanda koxinaniso kwizinto ezincinci ngelixa kuphuculwa ukuhanjiswa kwamandla. I-VIAS efihliweyo inceda ukugcina iibhodi zesekethe zilula kwaye zenziwe. Iimfama kwaye ukungcwatywa yiziyolisile zisetyenziswa ngokukodwa kuyilo oluntsonkothileyo, ubunzima obukhanyisiweyo, kunye nemveliso yexabiso eliphezulu le-elektroniki enje ngeIifowuni, iitafile, kwayeizixhobo zonyango.

I-Vias engaboniyozenziwa ngokulawula ubunzulu bokumba okanye i-laser. Le yokugqibela okwangoku yindlela eqhelekileyo. Ukuphathwa kwe-Holes yenziwa ngokulandelelana. Isiphumo semingxunya sinokufakwa okanye sisongelwe, songeza amanyathelo ongezelelweyo emveliso kunye novavanyo kunye neendleko.

Ngokwenjongo nomsebenzi wemingxunya, banokuhlelwa njenge:

Ngemingxunya:

Ziyimingxunya yensimbi esetyenziselwa ukufezekisa unxibelelwano lombane phakathi kweendawo ezahlukeneyo ze-PCB, kodwa hayi ngenjongo yokufumana izinto.

I-PS: Veale imingxunya inokwahlulwa ngakumbi kwi-Hole, umngxunya ongcwatywe, kunye nomngxunya ongaboniyo, kuxhomekeka kulusu olwenziwa umngxunya kwi-PCB njengoko kuchaziwe apha ngasentla.

Imingxunya yecandelo:

Zisetyenziselwa ukuthengisa nokulungisa iplagi-kwizinto ze-elektroniki ezikwi-elektroniki, kunye nemingxunya esetyenziselwa unxibelelwano lombane phakathi kweendawo ezahlukeneyo zokuhamba. Imingxunya yecandelo idla ngokuqina, kwaye inokusebenza njengendawo zokufikelela ezinqeni.

Imingxunya yokunyuka:

Ziyimingxunya emikhulu kwi-PCB esetyenziselwa ukhuseleko kwi-PCB ukuya kwi-casing okanye esinye isakhiwo senkxaso.

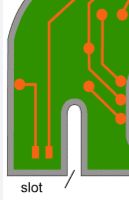

Imingxunya yeSlot:

Zisenziwa ngokuzenzekelayo zidibanisa imingxunya emininzi enye okanye nge-milling grooves kwiprogram yokuqhuba yomatshini. Zisetyenziswa ngokubanzi njengendawo ezikhulayo zezikhonkwane zexhumi, ezinjengemigca ye-oval yesokethi.

Imingxunya yasemva:

Ziyimingxunya enzulu kancinane ikhutshelwe ngaphandle kwemingxunya kwi-PCB yokwahlula i-stib kunye nokunciphisa ukubonakaliswa kwesibonakaliso ngexesha losulelo ngexesha lokuhambisa.

Ukulandela imingxunya encedisayo ukuba abavelisi be-PCB banokuyisebenzisa kwiInkqubo yeMveliso yePCBIinjineli zoyilo zePCB kufuneka ziqhele:

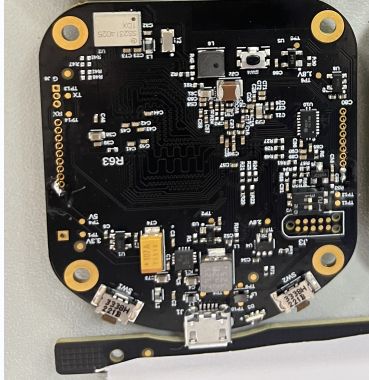

● Ukufumana imingxunya yimingxunya emithathu okanye emine ngaphezulu nasezantsi kwePCB. Eminye imingxunya ebhodini ihambelana nale mingxunya njengendawo ekubhekiswa kuyo kwizikhonkwane zokubeka izikhonkwane kunye nokulungiswa. Kwakhona eyaziwa njengezingcango zethagethi okanye imingxunya ekujoliswe kuyo, ziveliswa ngomatshini wokujongwa kwethagethi (umatshini wokuphuphuma kwe-punching okanye umatshini we-ray ray.

●Ukulungelelaniswa kwe-INRERRRImingxunya yenye imingxunya emaphethelweni yeBhodi yeZilayidi, isetyenziselwa ukufumana ukuba kukho nakuphi na ukuphambuka kwiBhodi yeZilayidi zeZilayidi ngaphambi kokuba idlwengule ngaphakathi kweBhodi. Oku kumisela ukuba ngaba inkqubo yokuqhuba kufuneka ilungiswe.

● Imingxunya yekhowudi ilandelana imingxunya emincinci kwelinye icala leBhodi esetyenziselwa ukubonisa ulwazi oluthile lolwazi, njengemodeli yemveliso, ikhowudi yokusebenza, iifeksi ezininzi zisebenzisa i-laser comark, njl njl.

● Imingxunya ye-Fudual yimingxunya yobukhulu obahlukeneyo kumphetho weBhodi, isetyenziselwa ukuchonga ukuba i-Drill Seameter ichanekile ngexesha lenkqubo yokuqhuba. Kule mihla, iifektri ezininzi zisebenzisa ezinye iitekhnoloji zale njongo.

● Iithebhu ezichithakeleyo zibeka imingxunya esetyenziselwa ukucheba i-PCB kunye nohlalutyo ukubonisa umgangatho wemingxunya.

● Imingxunya yovavanyo lokuvavanya ifakwe imingxunya esetyenziselwa ukuvavanya ukufuya i-PCB.

● Imingxunya yokulindela idla ngokubekwa imingxunya engafakwanga isetyenziselwa ukuthintela iBhodi ukuba ibekwe ngasemva, kwaye ihlala isetyenziswa xa kusenziwa iinkqubo zokubumba okanye zokucinga.

● Imingxunya yokuthoba iposti ingenzi imingxunya engafakwanga kwiinkqubo ezinxulumene nazo.

● Imingxunya ye-Rivet ayizibeki imingxunya engafakwanga esetyenziselwa ukulungisa i-rivets phakathi komaleko ngamnye wezinto eziphambili zezinto kunye nephepha elinobuhlungu ngexesha lokufakwa komntu kwiBhodi ye-Multilayer. Isikhundla se-rivet kufuneka sikhutshwe ngexesha lokuqhuba ukuthintela amaqabu ukuba ashiye eso sikhundla, enokubangela ukuba kwaphulwe kwiBhodi kwiinkqubo zamva.

Ibhalwe yi-ANKE PCB

IXESHA LOKUQALA: Jun-15 ukuya kwi-2023