Izixhobo zeNdibano yePCB

I-ANKE PCB ibonelela ngokukhethwa kwezixhobo ze-SMT kubandakanya isikhokelo, ezizenzekelayo kunye neeprinta ezizenzekelayo ezizenzekelayo, i-Pick kunye ne-Matshini yeNdawo yeBenchp ye-Bench Pounds kwiNdibano yeNkathi ye-Bround.

Kwi-Anke PCB siqonda ngokupheleleyo i-SUSTINIS YENKCUKACHA YENKCUKACHA KUNYE NOKO KUKHONA INDAWO YOKUGQIBELA YENKCAZO YOKUGQIBELA EYENZIWEYO YENKCAZO YOKUGQIBELA NEENKCUKACHA ZESICWANGCISO SE-PCB.

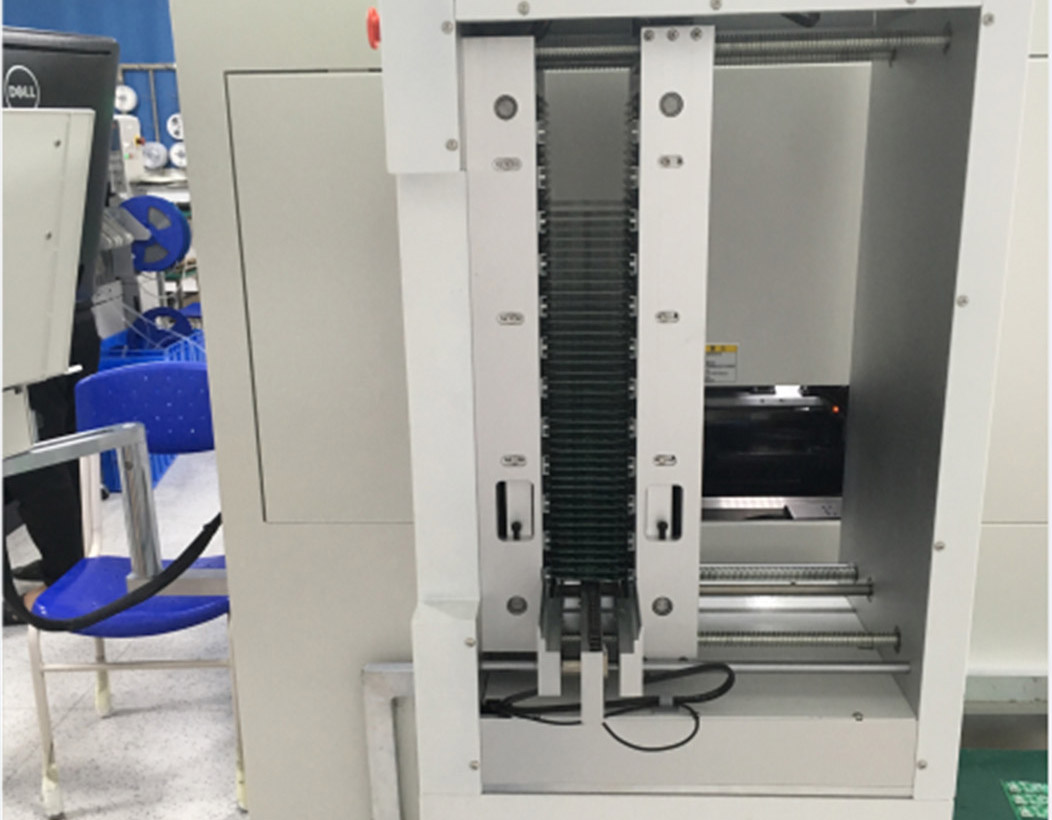

I-PCB yePCB ye-PCB

Lo matshini uvumela iibhodi ze-PCB ukondla kumchweli weThuthi yeTekisi ozenzekelayo.

Inzuzo

Ukugcina ixesha lokugcina abasebenzi

Ukugcinwa kweendleko kwimveliso yendibano

Ukunciphisa impazamo enokubangelwa yincwadana yemigaqo

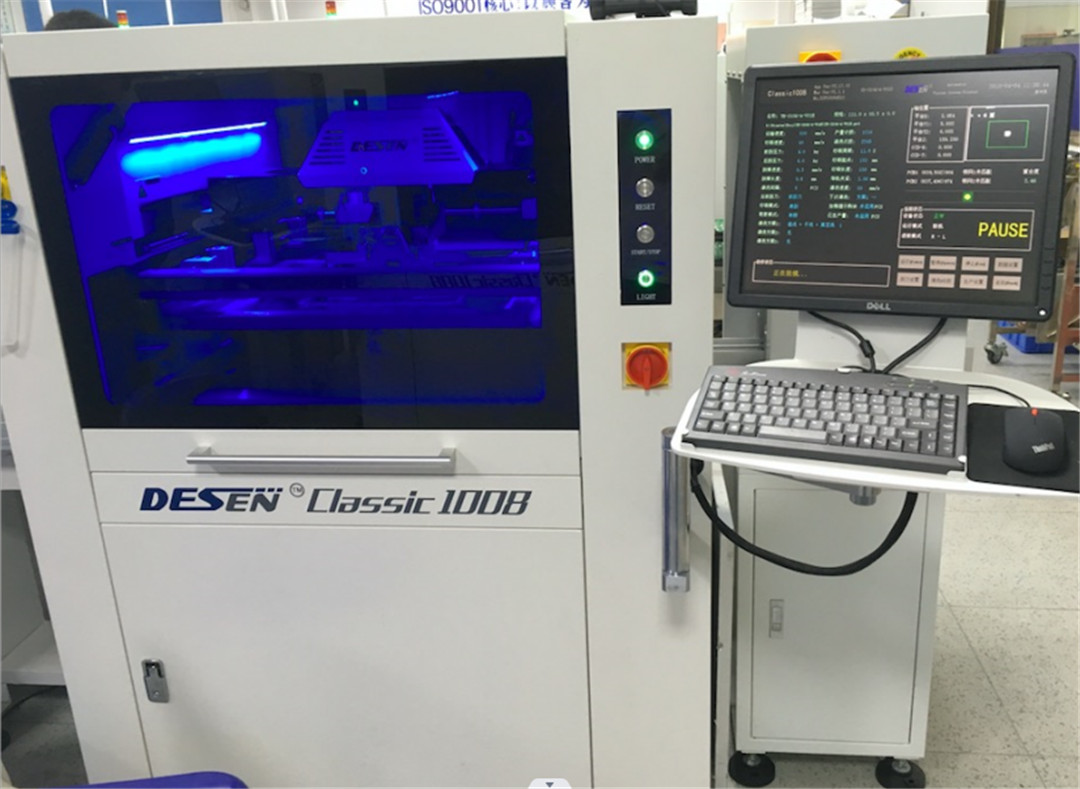

Umshicileli we-oftelic ozenzekelayo

I-ANKE inezixhobo zangaphambili ezinje ngoomatshini bokushicilela ezenzekelayo.

• Iyasebenza

Inkqubo ye-squeeee

Inkqubo yeStelicalls

Inkqubo yokucoca ezimeleyo

• Ukudluliselwa kwe-PCB kunye nenkqubo ye-PCB kunye nenkqubo ye-PCB

• Isinxibelelanisi sokusetyenziswa ngokulula

Inkqubo yokufaka umfanekiso

Ukuhlolwa kwe-2D kunye ne-SPC

• Ulungelelwaniso lwe-CCD

• Uhlengahlengiso lwe-PB oluzenzekelayo

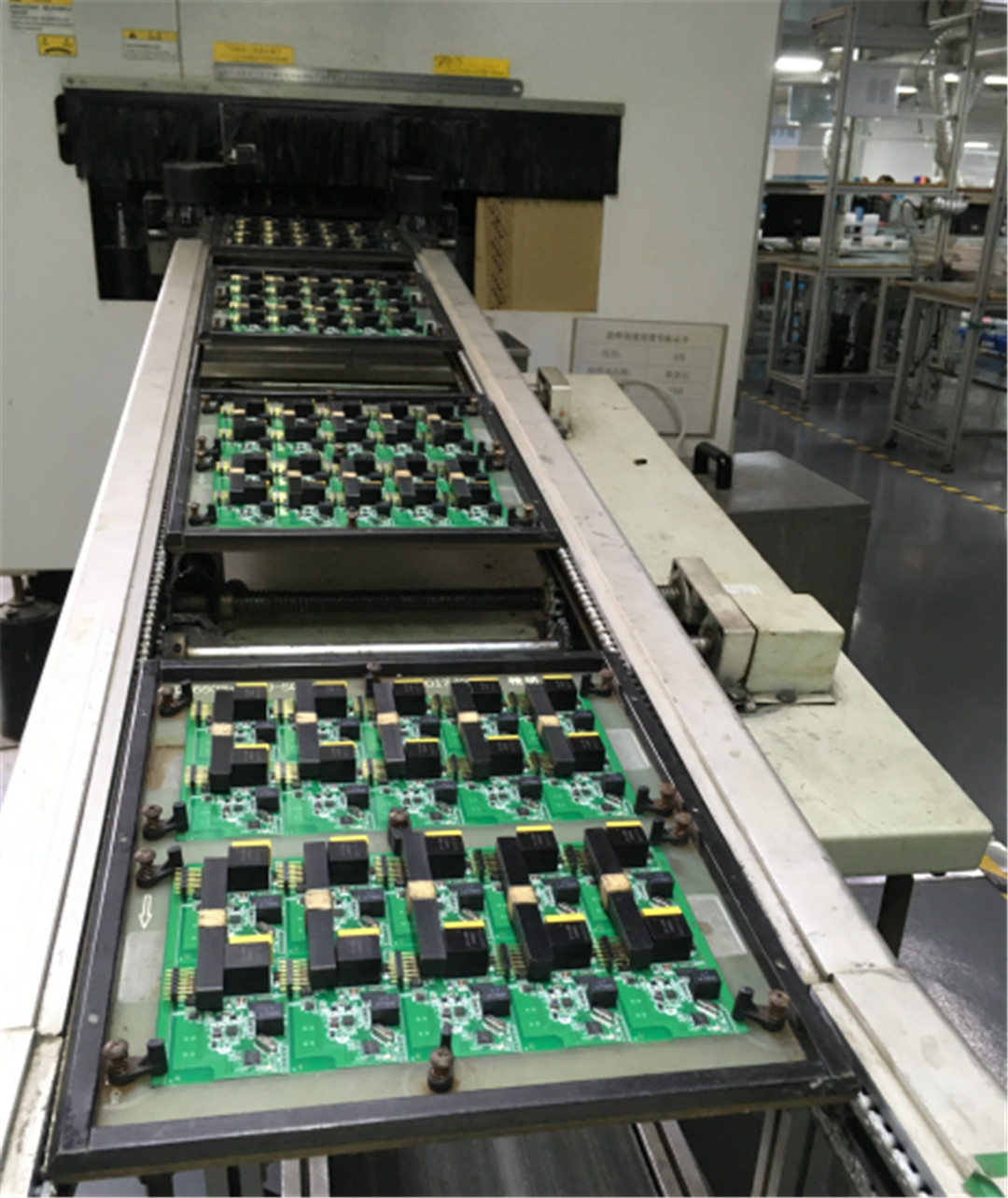

I-SMT Pick kunye neMatshini yeNdawo

• Ukuchaneka okuphakathi kwe-01005, 0201, iSob, i-PLCC, i-BGA, i-MBGA, i-CSP, i-QFP

• Ukungaqhagamshelwa kwenkqubo yekhowudi yekhowudi ye-intanethi yokuphinda-phinda kunye nokuzinza

Inkqubo ye-Smart Fentreer ibonelela ngendawo yokujonga ngokuzenzekelayo, ukubalwa kwezinto ezizenzekelayo, ukuvelisa idatha yedatha

• Ukugqibelela kwimveliso encinci nephakathi nephakathi

• Inkqubo yolungelelwaniso lweCognex "Umbono kwimpukane"

Inkqubo emazantsi yolungelelwaniso lwenkqubo ye-pitch ye-qpp ye-qpp & Bga

• Inkqubo eyakhiwe-yekhamera eneempawu ze-Auto Smart Fideial Spring

Inkqubo yokuhlambela

• Ukuhlolwa kombono ngaphambi nasemva kwemveliso

• Ukuguqulwa kwe-CAD United

Ixabiso lokubeka: I-10,500 CPP (IPC 9850)

• Iinkqubo zebhola zebhola kwi-X- kunye ne-axes

• Ifanelekile i-160 ye-AUTE YOBUGCISA

I-Coude-Free Relow Shicip / Shind-Fide

• Isoftware yokuSebenza ye-Windows XP yesoftware ye-Chinese kunye nesiNgesi. Yonke inkqubo phantsi

Ulawulo lokudibana lunokuhlalutya kwaye lubonise ukungaphumeleli. Yonke idatha yemveliso inokugcinwa ngokupheleleyo kwaye ihlalutye.

I-PC & Nememens Iyunithi yokulawula i-PSC enemisebenzi yokusebenza ezinzileyo; Ukuchaneka okuphezulu kweprofayili kunokuphepha ilahleko yemveliso ejongene nokusebenza okungaqhelekanga kwekhompyuter.

Uyilo oluvela kwi-thermal lungelelo lwemimandla yokufudumeza ukusuka kumacala ama-4 ibonelela ngobushushu obuphezulu; Umahluko weqondo lobushushu oluphezulu phakathi kwemimandla emi-2 edibeneyo inokuphepha ukuphazamiseka kobushushu; Inokuthintela umahluko wobushushu phakathi kobungakanani obukhulu kunye nezinto ezincinci kwaye zihlangabezane nemfuno yomthengisi yePCB entsonkothileyo.

• Ukunyanzelwa komoya okupholayo okanye i-chiller epholileyo yesantya esifanelekileyo sokupholisa ilungele zonke iintlobo ezahlukeneyo ze-Contif Conti.

• Ukusetyenziswa kwamandla asezantsi (8-10 kWh / iyure) ukugcina iindleko zokwenza imveliso.

I-AOI (inkqubo yokuhlola eyakhiweyo yokuhlola)

I-AOI sisixhobo esifumanisa iziphene eziqhelekileyo kwimveliso ye-welding ngokusekwe kwimigaqo yoqobo. I-AOL yitekhnoloji yokuvavanya, kodwa ikhula ngokukhawuleza, kwaye abavelisi abaninzi baye basungula izixhobo ze-AL.

Ngexesha lokuhlolwa ngokuzenzekelayo, umatshini ubeka ngokuzenzekelayo i-PCBA ngekhamera, uqokelele imifanekiso, kwaye uthelekise ukudibanisa umrhwebi ofunyenweyo kunye neeparamitha ezifanelekileyo kwidatha. Ukulungiswa kwelungisa.

Isantya esiphezulu, itekhnoloji yokulungisa imbonakalo yombono eninzi isetyenziselwa ukufumanisa iimpazamo ezahlukileyo zokubeka kunye neziphene ezingekho phantsi kwiBhodi ye-PB.

Iibhodi zePC zisuka kwiibhodi ezixineneyo ze-Pitch ePhezulu kwiBhodi yoBungakanani obuNcinci boBungakanani, ukubonelela ngezisombululo zokuhlolwa kwelayini yokuphucula ukusebenza kunye nomgangatho wemvelaphi.

Ngokusebenzisa i-AOL njengesixhobo sokunciphisa isiphene, iimpazamo zinokufumaneka kwaye zipheliswe ekuqaleni kwenkqubo yendibano, zikhokelela kulawulo lwenkqubo elungileyo. Ukufunyanwa kwangoko kweziphene kuya kuthintela iibhodi ezimbi ekubeni zithunyelwe kwizigaba zendibano ezalandelayo. I-AI iya kunciphisa iindleko zokulungisa kwaye kuthintelwe iibhodi zokukhwela ngaphandle kokulungiswa.

I-3D x-ray

Ngophuhliso olukhawulezileyo lwetekhnoloji ye-elektroniki, i-mineting yokupakisha, indibano exineneyo, kunye nokuqhubeka kokuvela kweetekhnoloji ezahlukeneyo zokupakisha, iimfuno zomgangatho wendibano wesekethe ziphakame kwaye ziphezulu.

Ke ngoko, iimfuno eziphezulu zibekwe kwiindlela zokuchonga kunye netekhnoloji.

Ukwenzela ukuhlangabezana nale mfuno, itekhnoloji entsha yokuhlola ihlala ivele, kwaye i-3d i-Q-ray yovavanyo lwe-X-ray i-x-ray yovavanyo ngummeli oqhelekileyo.

Ayinakukufumanisa kubonana i-Tonisar engabonakaliyo kuphela, njenge-BGA (i-GAL Crid Arrey, iphakheji yebhola ye-Grid), njl njl.

Okwangoku, iintlobo ezahlukeneyo zovavanyo zisetyenziswa kwicandelo lokuvavanywa kwendibano ye-elektroniki.

Ukuxhotyiswa okuqhelekileyo kukufumana uvavanyo olubonakalayo (MVI), kwi-Tester yeSekethe (ICT), kunye ne-Optical Optical

Ukuhlolwa (uhlolo oluzenzekelayo oluzenzekelayo). I-AI), uhlolo lwe-X-ray oluzenzekelayo (i-AXI), i-tester esebenzayo (ft) njl.

Isikhululo sePCBA sokusebenzela

Ngokuya kufikelela kwinkqubo yokusebenza kweNdibano ye-SMT, inokwahlulwa kuba linyathelo eliqela njengokuphela kwebala, indawo yokuphinda isebenze, ukucoca i-PCB, indawo yokuhlelwa kwecandelo, i-welding, kunye nokucoca.

1. I-Desolding: Le nkqubo kukususa izinto ezilungisiweyo kwi-PB yezinto ezisisigxina zeSMT. Owona mgaqo usisiseko awuyonakalisi okanye wonakalise izinto ezisusiweyo ngokwabo, izinto ezingqonge kunye neepadb zePCB.

2. Inxalenye yecandelo: Emva kokuba izinto ezihlaziyiweyo zibakwenziwa, ukuba ufuna ukuqhubeka nokusebenzisa izinto ezisusiweyo, kuya kufuneka uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde uphinde.

I-3. I-PCB Pad Ukucoca: Ukucoca i-PCB Pad kubandakanya umsebenzi wokucoca kunye nolungelelwaniso lomsebenzi. Ukuphawula i-pad kuhlala kubhekisa kwinqanaba le-PCB PAD yesixhobo esisusiweyo. Ukucoca i-pad kuhlala usebenzisa iThuthi

Isixhobo sokucoca, njenge-iron yomthengisi, isusa i-tsertid ye-speds kwipads, emva koko isule ngotywala okanye isinyibilikisi evunyiweyo ukususa iintlawulo kunye nezinto ezishiyekileyo.

I-4. Ukubekwa kwamacandelo: Jonga i-PCB ehlaziyiweyo nge-PCB eprintiweyo; Sebenzisa isixhobo sokubekwa kwecandelo lendawo yokufaka kwakhona ukukhetha i-nozzle efanelekileyo kwaye ulungise i-PCB yePCB ukuba ibekwe.

5. Ukuthengiswa: Inkqubo ethengiswayo yokusebenza kwakhona iyakwaziwa ngokwahlula-hlulwe ukuba kuthengwe incwadana yemigaqo kunye nokuthengiswa kwe-fitsow. Ifuna ukuthathelwa ingqalelo ngononophelo ngokusekwe kwicandelo kunye ne-PB, kunye neepropathi zezinto ezisetyenzisiweyo. I-Ilding ye-Ilding ilula kwaye isetyenziselwa ukuphinda iphinde isebenze ngamalungu amancinci.

I-Coum-Free Wave Umthengi oMthengisa

• Iskrafithi yokuCoca + Iyunithi yokuLawula i-PLC, ukusebenza kunye nokuthenjwa.

Uyilo oluhlaziyiweyo lwangaphandle, uyilo lwemodyuli yangaphakathi, hayi intle kuphela kodwa ikwalula ukuyigcina.

• I-flux spireer ivelisa i-atomition elungileyo nge-flux ephantsi.

• I-turbo fan i-fan enekhethini lokukhusela ukunqanda ukwahluka kwe-altomited Flume kwindawo yokuhamba, ekuqinisekiseni ukusebenza okukhuselekileyo.

• I-heater ye-heater echithekileyo ilungele ukugcinwa; Ukulawula ukufudumeza, ubushushu obuzinzileyo, ijika eligudileyo, ukusombulula ubunzima benkqubo yasimahla yenkqubo.

Iipani zeThuthi zisebenzisa amandla aphezulu, ukungakhathali kwentsimbi kuvelise ukusebenza okuphakathi kwenkohliso.

• I-nozzles yenziwa nge-titanuium qinisekisa ukusebenza kwe-therm ephantsi kunye ne-oxidation ephantsi.

Inomsebenzi wexesha lokuqalisa ngokuzenzekelayo kunye nokuvalwa komatshini uphela.

IXESHA LOKUQALA: UPE-05-2022